Product

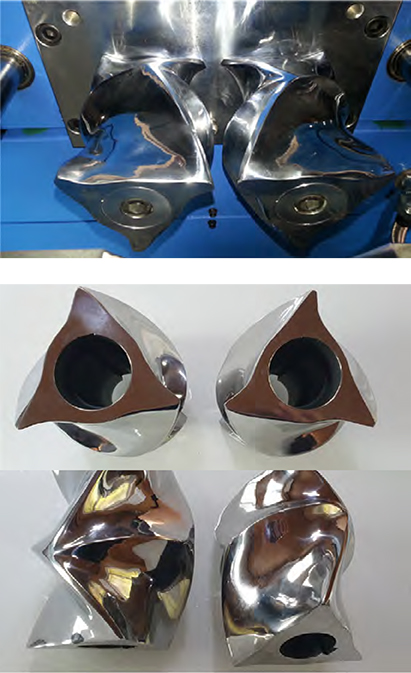

GREEN POLYTECH DISPERSION MIXERS

Ceramic Powder & Metal Powder Pellet MIXERS (세라믹 분말사출 & 금속분말 사출용 믹서)

An Unsurpassed Performance to Meet All Your Mixing Needs

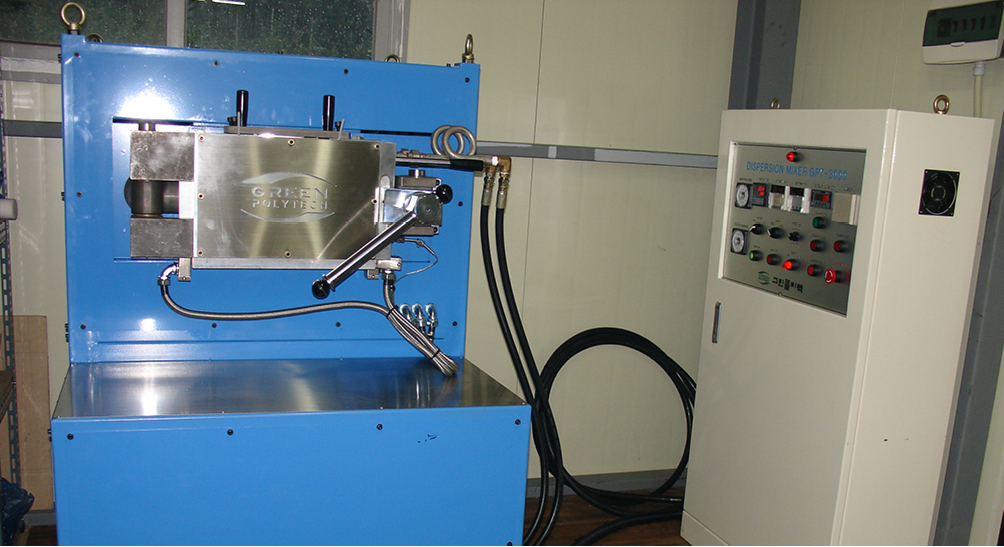

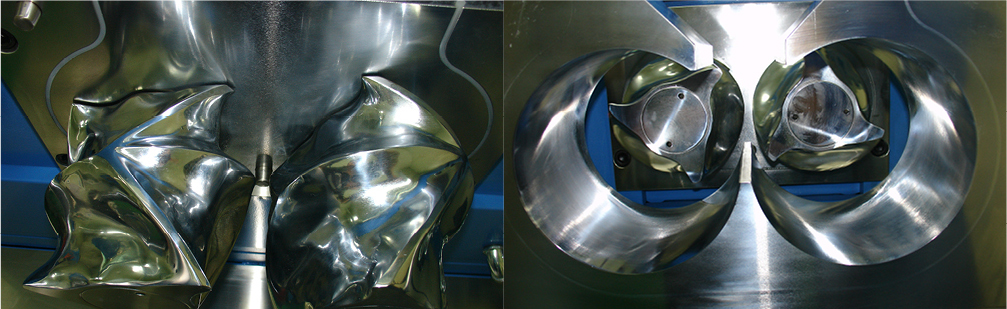

New composite materials are now being developed in rapid succession to meet the needs of industry. Green polytech's dispersion mixers are specially designed for the small-batch processing required by our ''new materials'' era. These timely mixers meet a wide variety of contemporary mixing needs. They offer an excellent mixing performance, superb dispersion characteristics, easy handling and user-friendly controls.

Feature

Though small in size, our dispersion mixers offer an number of excellent features.

- Efficiently mixes materials in small batches. (Mixing volume capacities are available: 0.5, 1, and 3 liters/batch.)

- Ideal for research and development of new materials and for test-mixing.

- Exceptionally useful in small-batch production and in pilot plants.

- Perfect for testing various mixing conditions.

- Simplifies production of sample materials.

Applications

Green polytech's dispersion mixers accommodate a broad range of materials.

-

Rubber compounds

By virtue of the low-temperature mixing feature, various compounding ingredients (filler) can be mixed with either natural rubber or synthetic rubber material.

-

Plastic compounds

Excellent for mixing calcium carbonate, talc, carbon black fillers, etc. into polymers.

-

Ceramics

Ideal for mixing thermoplastic resin, wax, additives, etc. with alumina and other substances.

-

Curing agent masterbatches

Because of the low-temperature mixing feature, a curing agent can be easily mixed with rubber or polymer.

-

Sealed materials for Electric-Magnetic wave

Facilitates mixing of electromagnetic-shielding metallic powder with rubber or polymer.

-

Plastic or rubber magnets

Excellent for mixing ferrite materials with rubber or polymer at a high filling rate.

-

Blending polymers

The powerful mixing performance offers good blending results with many different polymers.

-

Wood compounds

Wood flour or rice hull can be easily mixed with polymer.

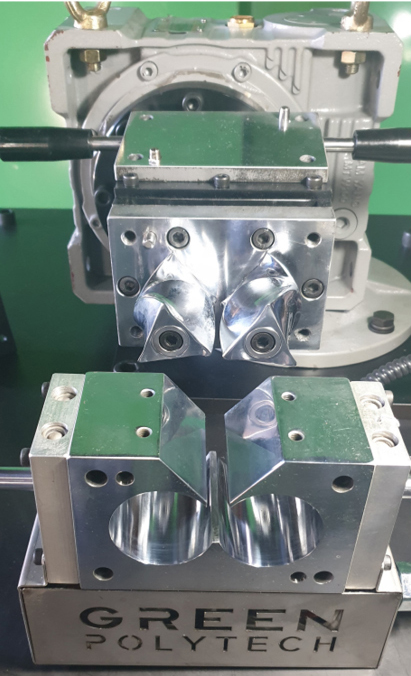

GPt-dm 3000

Good for a expensive materials.

- Mixing volume : 3.0 liter

- Motor : 10HP ( 7.5kW )

GPt-dm 1000 ~ 2000

- Mixing volume : 1000 ~ 2000cc

- Motor : 2 kW ~ 2.5 kw

GPt-dm 100 ~ 500

- Mixing volume : 100 cc

- Motor : 1.5kW ~ 2 kW

화장품 분말용 하이 스피드 믹서

- Mixing volume : 10000 cc

- Motor : 1kW & 2.5kW